BOOK AN APPOINTMENT

Book an Appointment

Glanville & Co. is an in-house, state-of-the-art, local manufacturing business, right in the heart of Sydney. We are using technology to assist us in the creation of innovative orchestral string instruments & accessories. It is through the fusion of both technology & tradition that we have been able to produce high-quality, customisable, innovative & affordable instruments.

While we launched our Glanville & Co. instruments in 2018, officially the journey began 27 years ago in the garage of Carmel & David Glanville. It was a very different business back then, but Carmel’s experience as a performer & teacher combined with David’s skills as a luthier is what has led the business to where it is today. Glanville & Co. is the newest business venture for the owners of The Sydney String Centre, collectively with their three children Doug, Libby & Max. Over the years, a heartfelt vision for music and education in Australia has remained one of the principal values for both The Sydney String Centre & Glanville & Co.

Glanville & Co. was founded on the belief that all Australians should have access to music education. It is well researched that music is indeed critical to the development of a child’s cognition & the advantages of music are far greater than just purely playing an instrument. When learning music, musicians & students require access to high quality instruments that will nurture their development & not hinder their growth or enjoyment. It is this philosophy that Glanville & Co. has been built on. Our dream is that all Australian students & musicians have access to learn & play on a proudly Australian made instrument.

The predominant business model for stringed instrument manufacture has been to import large quantities of instruments at a time from overseas, often from some of the poorest parts of the world & have them sent in a shipping container to their destination. This process has proven to be not as economical as it may seem on account of long wait times, inventory defects & the extensive storage space required to house the vast amount of inventory. We have found it to be a wasteful process that exploits some of the most vulnerable people in the world.

Australia is fortunate enough to have some exceptionally talented & prized instrument makers. However, the start to finish process is very detailed and time consuming. To make a violin requires a highly-trained professional & the resulting expense means that most Australian-made instruments are inaccessible for many hopeful players.

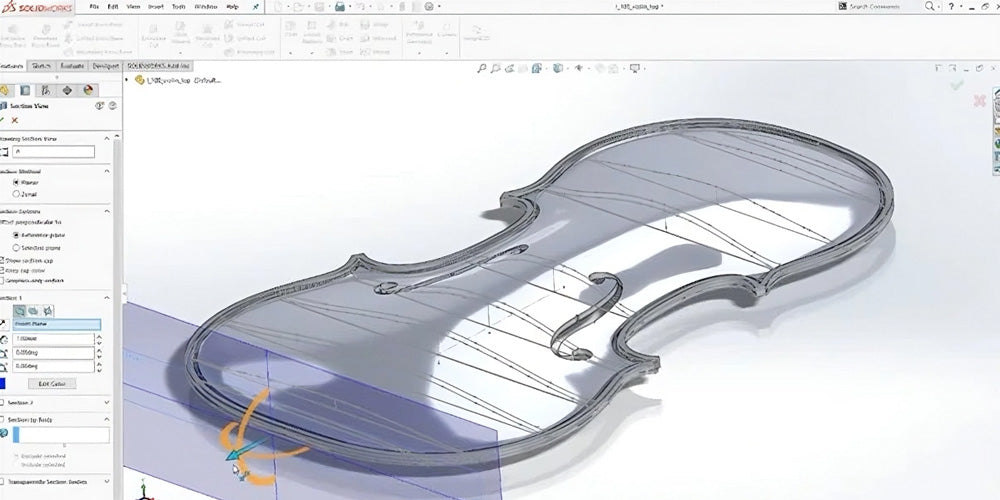

It is a combination of both technology & tradition that has made affordable violin-making in Australia feasible. Our initial Glanville & Co. instruments were modelled on various Stradivari & Guarneri violins, such as the legendary Messiah Stradivari. The plans for this particular violin were accessible to us & we were able to replicate & digitise them via CAD (Computer-Aided Design). Creating a 3D plan is particularly multi-faceted & time-consuming. It requires someone who has been trained to use the software and can translate the plans into production.

We are able to modify these 3D plans so that customers can request modifications as they like. It is possible to request a particular colour of varnish, scroll shape & design, instrument length & additional or less thickness in the neck. We can then save this catered design for a particular teacher & accurately recreate it for all their students if they have specific requirements.

Once the 3D plans have been completed, we use high quality European spruce & maple as they have for hundreds of years to build the body of the violin. Then our 5-axis Italian CNC machine (who we have nick-named ‘Tony’ after the legendary Antonio Stradivari) carefully reads the plans that we prepared & uses a variety of tools to sculpt select parts of the violin such as the top, back & scroll. Once these pieces come off the machine they are fine-tuned & assembled by hand.

Tony can follow instructions perfectly, but he is lacking the ability to make a decision. As a result, it goes without saying that a machine cannot do everything that is needed to make a violin in its entirety. A good violin maker is able to follow a plan perfectly. However, a stand-out violin maker is able to take that plan & digress from the design as needed when determined by the individual piece of wood or to achieve a particular tonal outcome.

To make an outstanding instrument, a skilled luthier is required. Preferably a violin-maker who can play the violin & has a good knowledge of the sound & set-up requirements of musicians. On each one of our violins the assembling, rib-bending, purfling, varnishing and set-up are done by our highly-skilled & trained luthiers.

Essentially, the non-value adding work that does not need a decision to be made but requires consistency, is done by Tony. The parts that are produced by Tony still have a considerable amount of work that needs to be completed by hand once he has finished with them. However, each part has enough room left on it to allow the team of luthiers to make adjustments & enhance the finished product in a way that only a human can.

Many musicians are resistant to the notion of a machine-made instrument. Violin in particular being an intimate instrument is easy to romanticise in terms of its origins and the time, effort & hard work that went into the making. These musicians can rest assured that a multitude of time, effort & hard work has gone into the resulting violins from Glanville & Co. This has been possible by looking at the process of both importing & making a violin with fresh eyes. There is modern craftsmanship in what Glanville & Co. is doing, and the process & resulting end product are still beautiful.

The Maple & Spruce used to make these instruments is sustainably sourced from Germany, excluding the wood used in the fingerboards & pegs which is sourced from areas such as Africa & India. Glanville & Co. are researching alternative materials that don’t compromise on sound & could potentially replace some woods such as ebony & rosewood that will eventually be endangered. Furthermore, for every 10 violins that are sold by Glanville & Co. they will make a donation to the Australian Koala Foundation to plant a tree.

Glanville & Co. is passionate about providing a good selection of high-quality, customisable & affordable instruments. Through local production, they maintain control over customer wait-time & inventory defects, while reducing their environmental impact. They hope to contribute to the local community, providing a better service that knows & understands the individual musicians needs, keeps local ownership & provides good jobs. Glanville & Co. hope to not only positively affect & make a unique mark on the Australian instrument manufacturing industry but also to invest in innovation & inspire the next generation of luthiers to keep violin-making alive in Australia.

The Sydney String Centre sits on the unceded lands of the Gamaragal people. We pay our respects to Elders and communities past, present, and emerging. We celebrate the stories, culture and traditions of Aboriginal and Torres Strait Islander people who also work and live on this land.